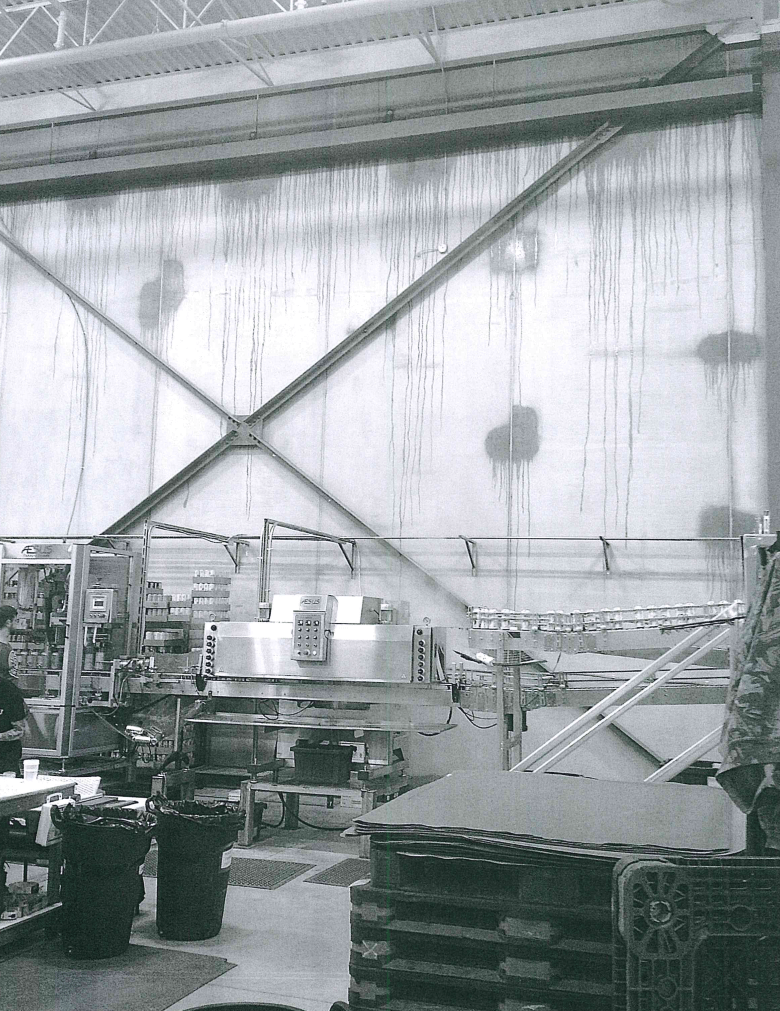

The manufacturing facility has a hot water washing process that generates a lot of steam that was spreading through the building. This steam was generating heat and condensing on the ceiling and other surfaces. Their worries were increased temperatures, degradation of their building envelope and potential damage to other process equipment.

The Solution

The O’Dell solution was to create an exhaust system to capture the steam generated from this process. Our expert knowledge on kitchen hood system was utilized as we often supply SpringAir Type II condensate hoods to capture steam from dishwashers. Similar principles were applied here. A SpringAir condensate hood was sized to overhang the process equipment so that when the doors are opened the steam would travel up into the hood. A PennBarry roof mounted upblast exhaust fan was sized at 200 cfm/ft to ensure the steam was pulled into the hood. The condensate hood includes integral stainless baffles/condensate deflectors and a perimeter lip and drain connection around the inside bottom hood seam. The condensate hood is manufactured out of 18 GA. stainless steel.

Since the system was installed, the steam from this washing process is now safely captured, water drained and heat exhausted from the building.