The Paradigm Building is a 24-storey, 350-suite condominium located at Brant and Fairview Street East in Burlington, Ontario. With three high-rise towers (West, Central, and East), the building shares amenities, including an indoor pool, a gym, a party room, and a lobby on the lower levels, with the upper floors separated into individual towers.

Challenges

Our task involved providing make-up air (MUA) for each tower’s corridors, a dehumidification system with heat recovery for the indoor pool, fresh air for the amenity spaces, and general ventilation for individual suites. The design focus for modern condominiums like the Paradigm Building prioritizes maximizing usable space for condos and amenities, leading to restricted ceiling space and smaller mechanical rooms. Each system-specific restriction included:

- MUA Unit for Corridor Ventilation: Located in the mechanical room alongside other systems (boilers, chiller, DWHT), the MUA had to fit in a 14-foot wide by 12-foot long space while providing up to 27,000 CFM.

- Dehumidifier for the Indoor Pool: Positioned in the corner of a block wall, the ceiling height was only 9 feet, necessitating 6,000 CFM of ventilation air.

- Heat-Recovery Ventilator: Designed for the dehumidifier’s outside and exhaust air, it had to fit within a 20-inch ceiling space and withstand harsh pool chemicals.

The Solution

Working with various manufacturers, we provided tailored solutions for each application.

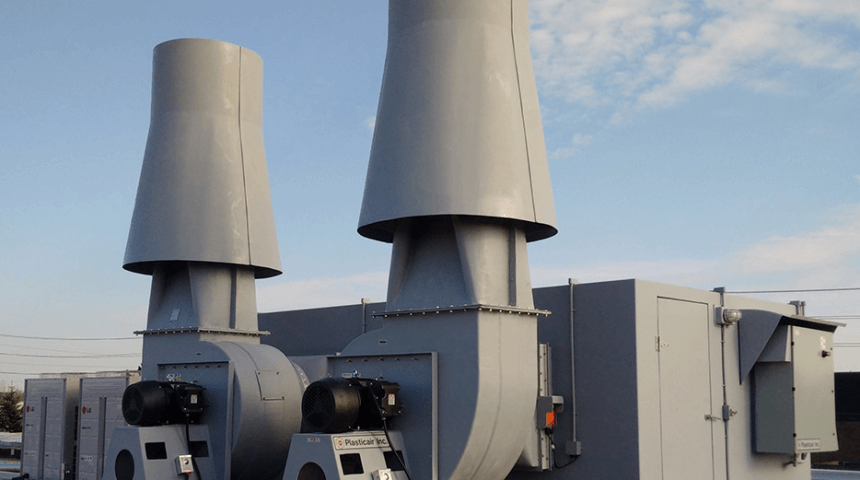

- MUA Unit: We selected a Krueger hydronic indoor air handler with numerous customizable options. It was shipped in three pre-assembled sections to fit through the block wall opening and assembled on-site. The unit, equipped with a variable frequency drive, modulated supply air from 20,000 CFM to 27,000 CFM. A vertical fan section was chosen and placed on top of the cooling coil section, accommodating the 12-foot length restriction.

- Dehumidifier: For the indoor pool, a vertical-style Dectron Dry-O-Tron was chosen, featuring a plenum fan on a variable frequency drive. This configuration allowed for a right-angle supply air discharge, fitting the mechanical room’s constraints.

- Heat-Recovery Ventilator (HRV): We selected a Building Performance Equipment (BPE) system, a core-only unit utilizing remote fans for supply and exhaust air. The HRV, made entirely of polypropylene, fit within the 20-inch high ceiling space when installed on its side.

Our Approach

Our team collaborated closely with G.S. Sheet Metal, the building’s engineers, and other stakeholders to develop innovative solutions that met the Paradigm Building’s specific needs. Through detailed site visits, consultations, and customized designs, we ensured each system was efficiently integrated within the space constraints while maintaining high performance.