Ventura Foods, located in Etobicoke, was experiencing significant challenges with their pneumatic conveyor system used to transport dry cocoa powder. The incumbent service contractor, A/C Air Systems, reached out to O’Dell to diagnose and address the persistent clogging issues caused by the warm, humid conditions in the plant. The moisture was absorbing into the cocoa powder, leading to obstructions that hampered production and increased downtime.

Challenges

The challenge was to address the ongoing clogging issues caused by cocoa powder absorbing moisture in the warm, humid environment of the plant. This moisture accumulation resulted in congealed cocoa in the pneumatic conveyor system, leading to unacceptable process downtime and impacting overall operational efficiency.

The Solution

After a thorough review of the process, we recommended installing a desiccant dehumidifier to provide dry air at the inlet of the pneumatic conveyor system.

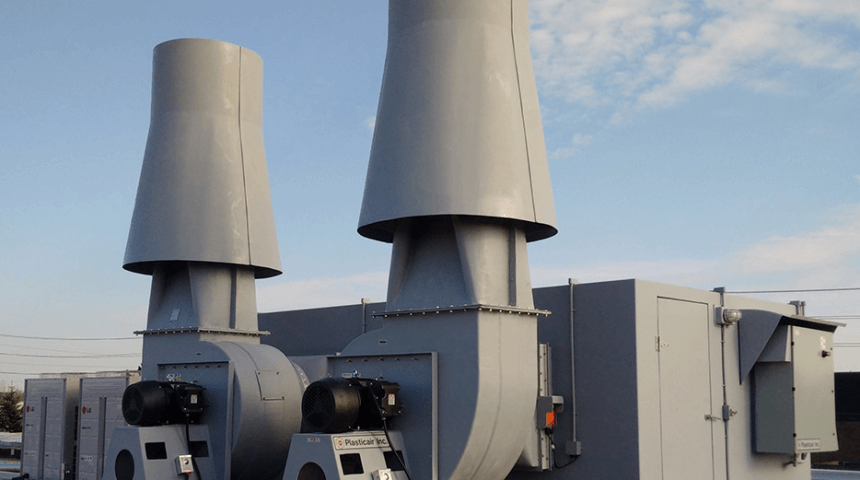

We installed a Novelaire DH1000 desiccant dehumidifier outside the bag hopper room. The dehumidifier’s supply was ducted to discharge directly above the conveyor inlet, ensuring a consistent flow of dry air. Return air to the dehumidifier was taken from the hopper room, which is now kept closed during operation to maximize efficiency. By recirculating the air back to the dehumidifier, we achieved a dew point discharge of -3°F over the conveyor inlet while maintaining the hopper room at a dew point of 35°F.

Our Approach

This solution effectively eliminated the clogging issues within the pneumatic conveyor system, resulting in:

- Increased operational efficiency by reducing process downtime

- Enhanced material handling of dry cocoa

- Improved climate control within the hopper room