LEED – Thermal Comfort (ADPI)

I recently worked with an engineer and contractor on a design build project where the owner wished to pursue LEED certification. One of the credits being pursued was thermal comfort. This credit requires the design to meet both thermal comfort and thermal control requirements.

Thermal control is quite straightforward as you need only provide controls for at least 50% of the individual occupants. Although easy, there are cost implications due to additional zoning and/or base air handling system configuration requirements.

The thermal comfort part of the credit takes a bit more calculation and attention to detail. For overhead air distribution, the requirements are as follows:

- Heating Mode – Maintain discharge air temperature no greater than 15F above ambient space conditions (i.e. 90F), and the 150fpm throw must reach within 4.5-ft from the floor.

- Cooling Mode – Design air distribution to maintain ADPI greater than 80.

With current construction standards and reductions in internal loads due to higher efficiency office equipment, meeting ADPI can be challenging. This is especially true in VAV systems where minimum airflows are being set at 30%. Standard diffusers just aren’t capable of providing sufficient throw to achieve acceptable ADPI. For illustration, let’s look at one of the rooms from my recent project.

Room Parameters

- 12′ x 12′ x 10′ (W x L x H)

- Design Airflow – 150-cfm

- VAV minimium setting – 45-cfm (30%)

- 2′ x 4′ t-bar ceiling

The first thing you need to do when calculating ADPI is figure out your characteristic length (L), which is defined as the distance from the diffuser to wall or centreline between 2 diffusers. For our example the characteristic length is 6-ft. (Note: Distance to the wall is 5-ft, but we add an additional foot to account for ceiling height of 10-ft. ADPI calculations are based off 9-ft ceilings so this adjustment is required.)

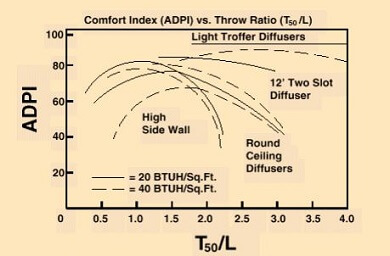

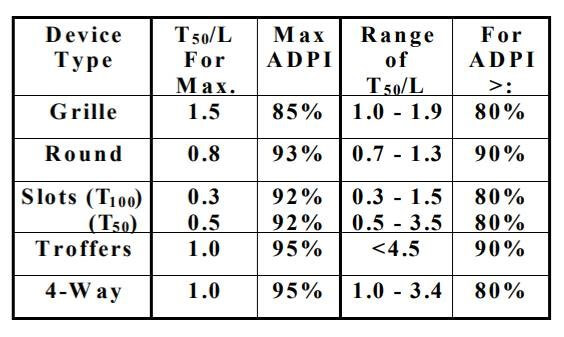

The next step is to determine the acceptable envelope of operation for the diffusers you’re planning on using. To do this, you will need to reference the ADPI selection guide in ASHRAE fundamentals. The following is an excerpt from that table.

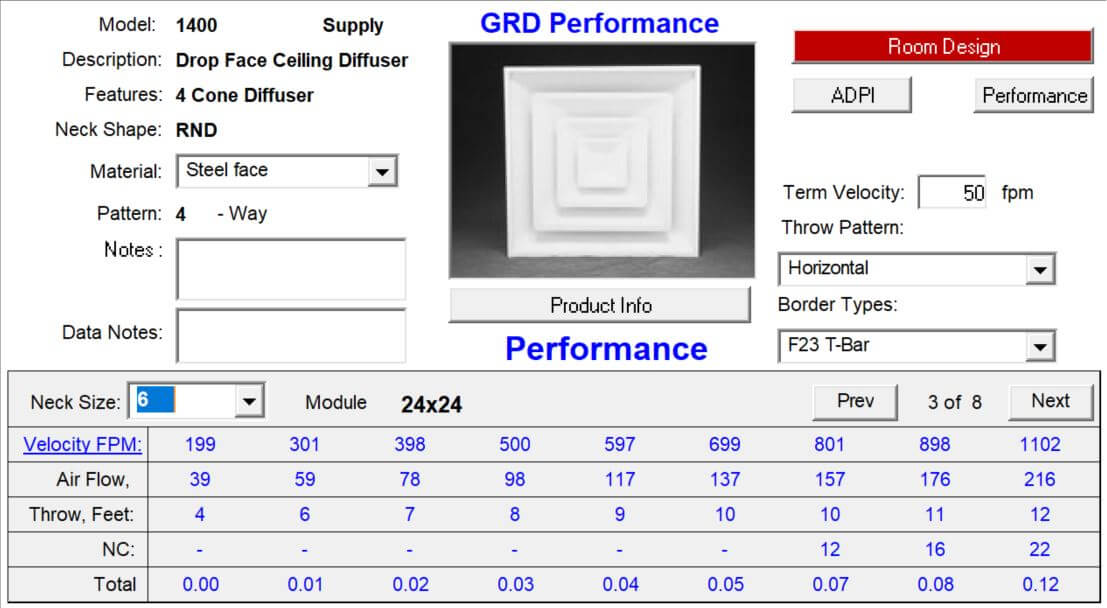

With the above chart, we are able to determine the 50-fpm terminal velocity required for acceptable ADPI. We planned to use the Krueger 1400 square cone diffuser, which is a typical selection in our market. This diffuser is considered a 4-way device and has a T50/L range of 1.0 to 3.4 for ADPI >80. So, we need to select the neck size that delivers 50-fpm velocity at a distance of 6 to 20.4-ft. I like to use the handy Krueger K-Select Program to get throw data for diffusers. (Click on image for full GRD performance output)

From this data, you can see that the minimum airflow to achieve acceptable ADPI for this diffuser is 59-cfm. This is a little more than the design minimum of 45-cfm. At this point, you have a couple options. You can either simply adjust the minimum for that space to maintain acceptable ADPI, or, you can look to a different device that accommodate the lower airflow.

If you’re looking to get this LEED credit, O’Dell can help! Contact Us for support.

Leave a Reply